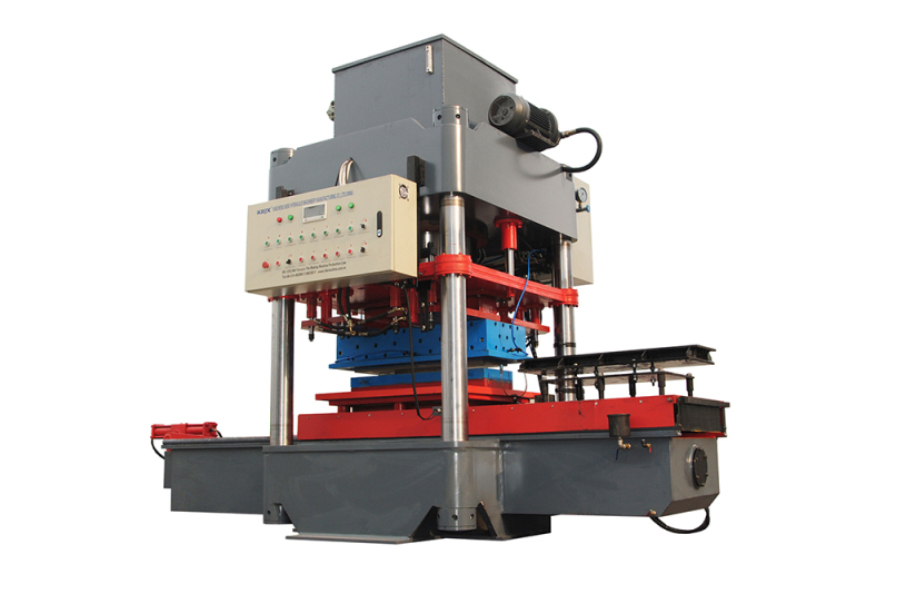

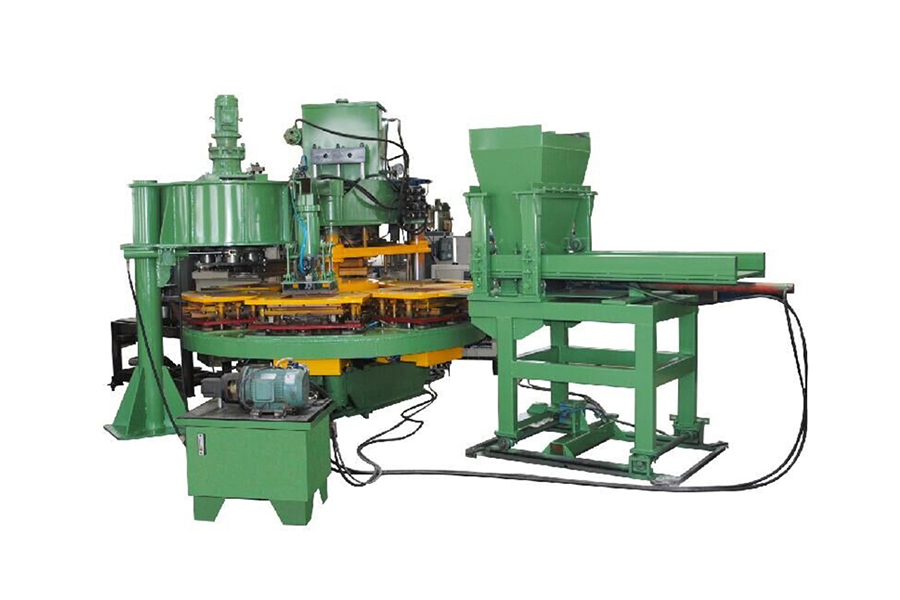

In the construction and decoration industry, high-end decoration projects have extremely high requirements for the flatness, dimensional accuracy, and surface quality of stone slabs. As a key processing equipment, Stone Calibration Machine adopts high-precision mechanical structure and advanced calibration technology, which can continuously and stably calibrate stone slabs during the processing. This high-precision calibration mechanism ensures that the flatness of stone slabs after processing meets extremely high standards, avoiding installation difficulties and poor decorative effects caused by uneven slabs.

The machine is equipped with a precision control system and adjustment device, allowing operators to adjust processing parameters such as calibration pressure, feed rate, etc. according to actual needs, in order to achieve precise control of the dimensional accuracy of stone slabs. This flexibility enables the Stone Calibration Machine to adapt to the processing of stone slabs of different specifications and requirements, ensuring that each product can achieve the dimensional accuracy required by the design.

In addition, in order to further improve the surface quality of stone slabs, the Stone Calibration Machine is also equipped with additional functions such as polishing and grinding. These functions can simultaneously improve the surface glossiness and delicacy of stone slabs during the calibration process, making them more in line with the aesthetic requirements of high-end decorative projects.

Tel:+86-15105109068

E-mail:[email protected]

REQUEST A QUOTE

REQUEST A QUOTE

English

English