| Main machine power | 24.5KW |

| Moulding pressure | 500T |

| Moulding speed | 1-2 pce/min |

| Main machine weight | 18T |

| External dimension | 4600*1830*3100mm |

|

|

|

|

| Main machine power | 24.5KW |

| Moulding pressure | 500T |

| Moulding speed | 1-2 pce/min |

| Main machine weight | 18T |

| External dimension | 4600*1830*3100mm |

|

|

|

|

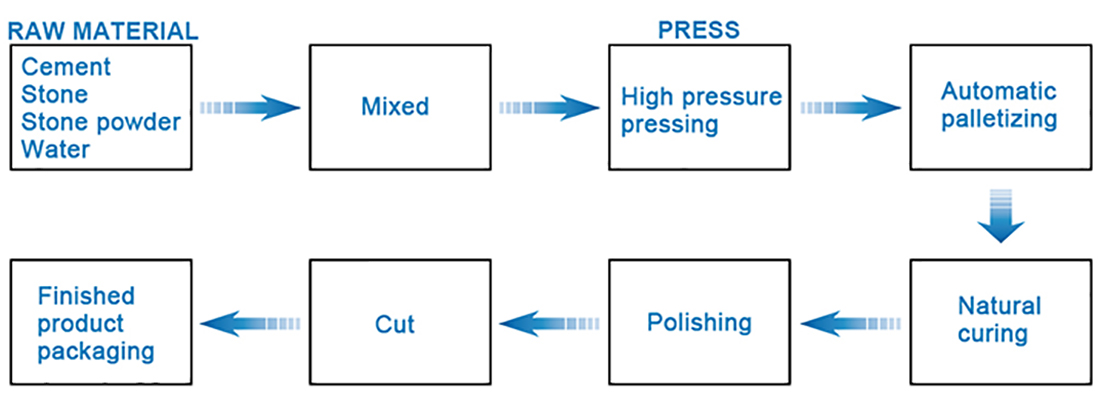

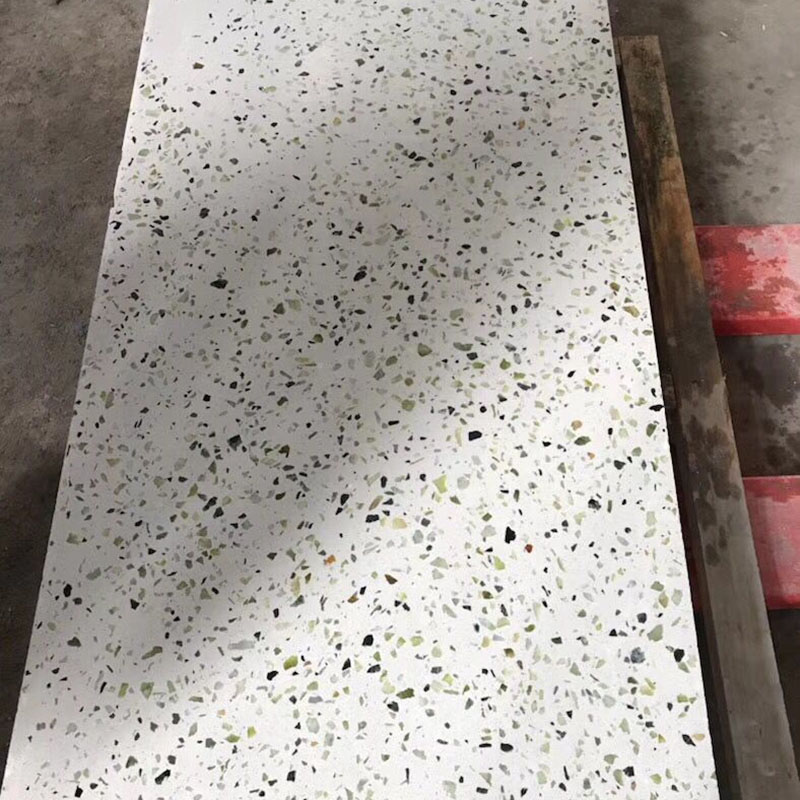

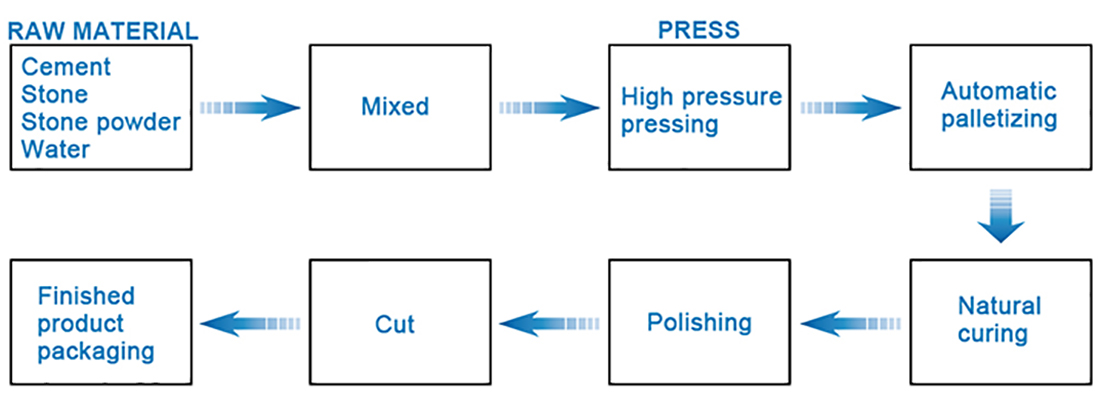

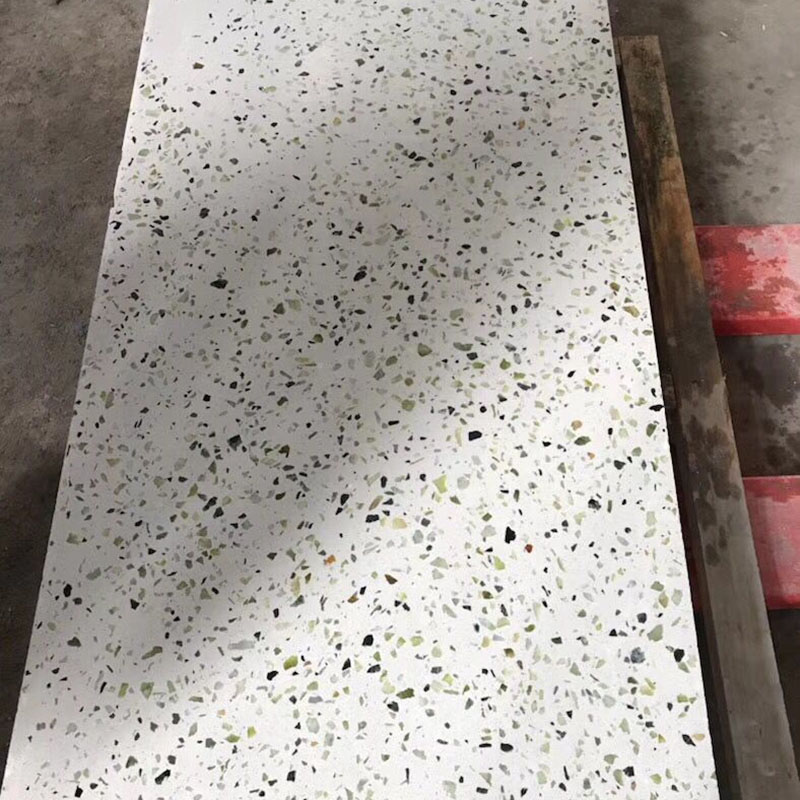

Yancheng Kebo Hydraulic Machinery Manufacturing Co., Ltd. is China KB125E 800 1200 Terrazzo Tile Machine Suppliers and Custom KB125E 800 1200 Terrazzo Tile Machine Factory. We have a wide range of products, including cement roof tile machine, terrazzo floor tile machine,concrete prefabricated tile machine,artificial stone machine, paving interlock tile machine, wet casting curbstone machine, stone polishing machine, stone shot blasting machine, mixer, cutter, etc. We constantly pursue technological innovation and product optimization, and are committed to providing customers with high-quality and high-efficiency equipment. Our products undergo strict quality control and testing to ensure their stability, reliability and durability. We attach great importance to the needs of our customers and provide customized solutions according to their specific requirements. We will continue to work hard to provide customers with quality products and services. As a professional manufacturer of terrazzo machine, our customers all over the country and exported to Algeria, India, Vietnam, Brazil, Ukraine and many other countries.

In the new century full of opportunities and challenges, pragmatic "KB people" will grasp the opportunity with hard work and wisdom to meet the challenge. We are willing to cooperate with friends from all walks of life with complete technology, mutual benefit, common development and grand business!

Before using the Double Layer Terrazzo Tile Machine, it is essential to carry out comprehensive preparations to ensure efficient operation of the equipment and ...

In the modern building materials industry, production efficiency and product quality are key factors for corporate competitiveness. With its unique double-layer...

Efficient and stable hydraulic transmission systemHydraulic transmission technology plays an indispensable role in the production process of concrete cement til...

In the modern construction industry, concrete cement tiles are widely used due to their excellent performance and economy. In order to ensure production efficie...