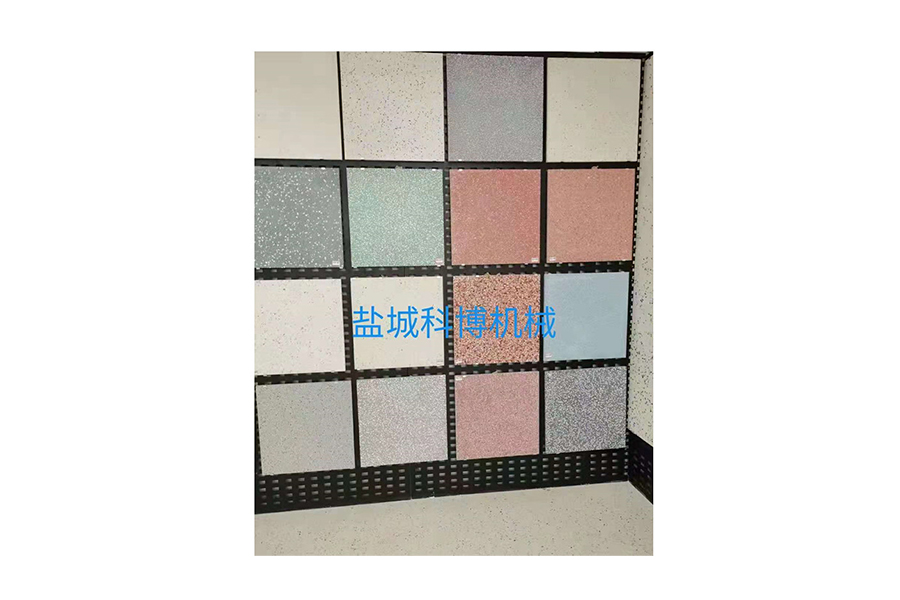

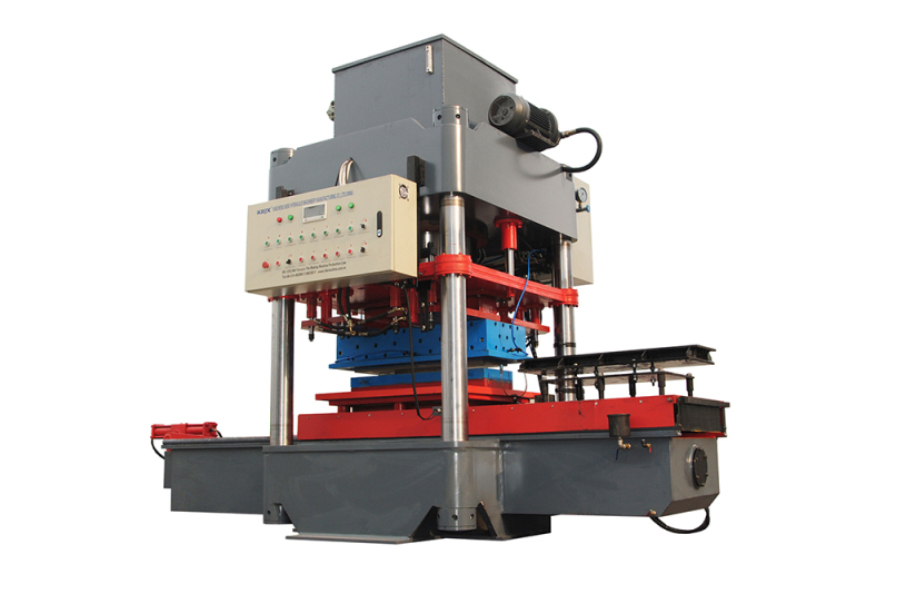

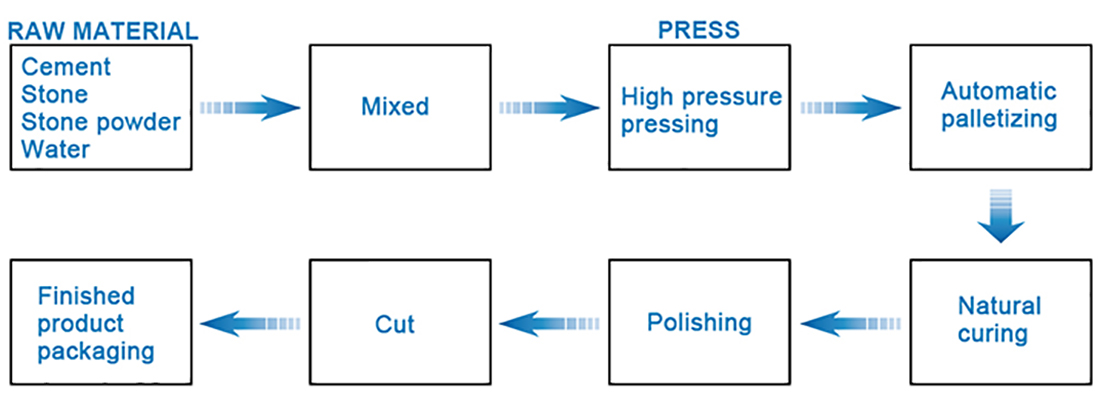

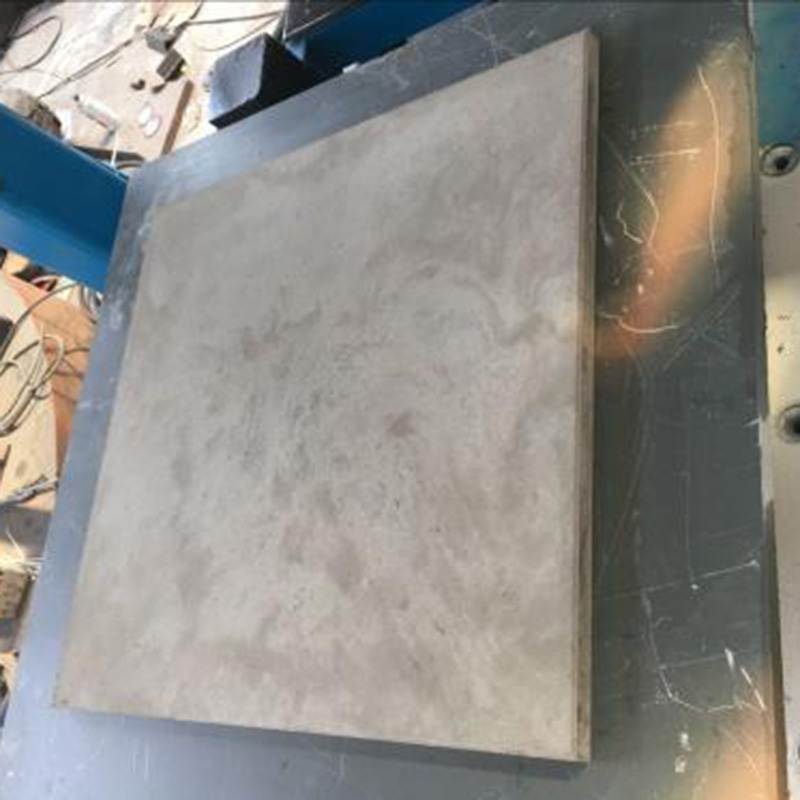

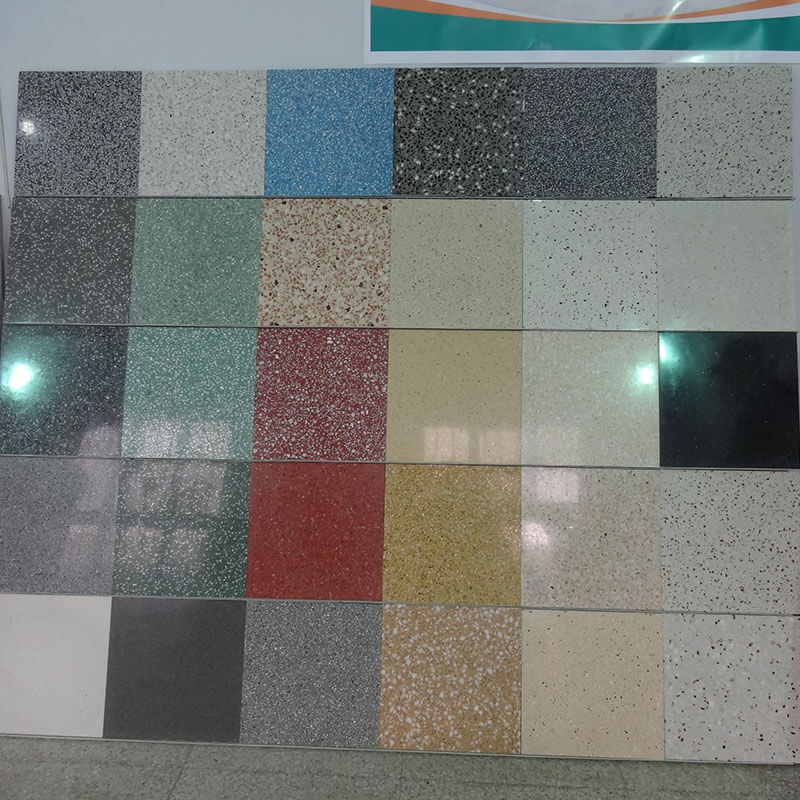

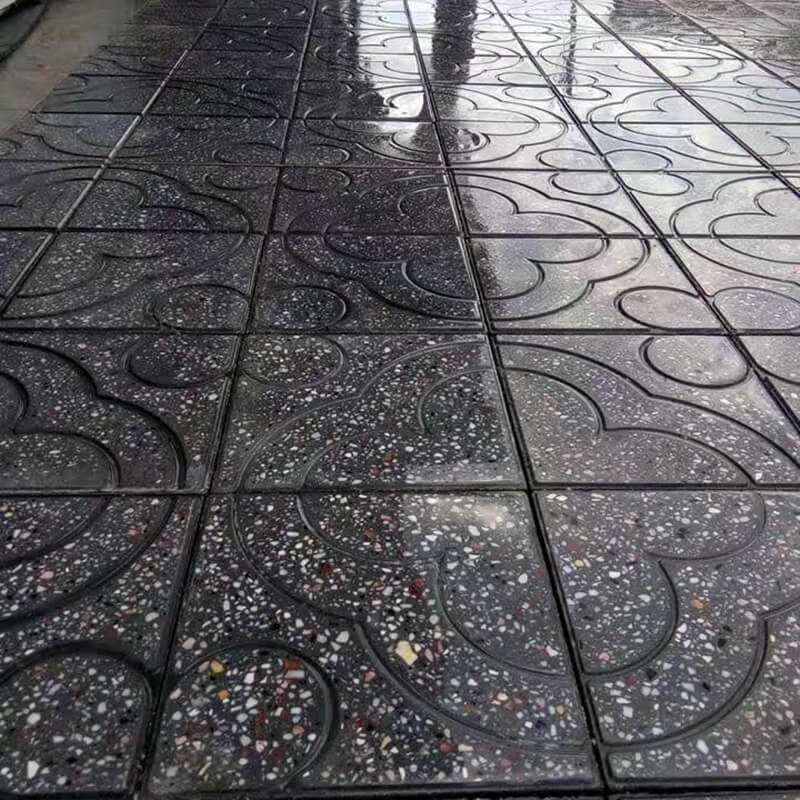

This machine is mainly for PC brick, roof tile, slab and stair steps, and other concrete tiles. The size of 500*500, 600*600, 400*400, 300*300, 600*300, 500*250mm...

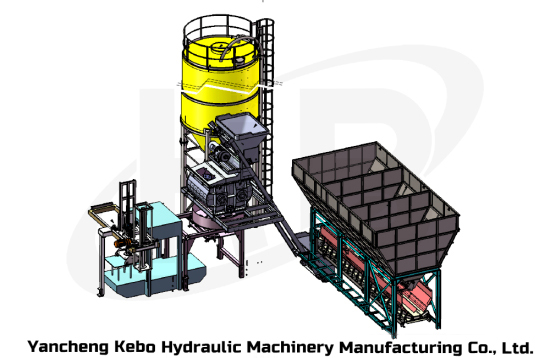

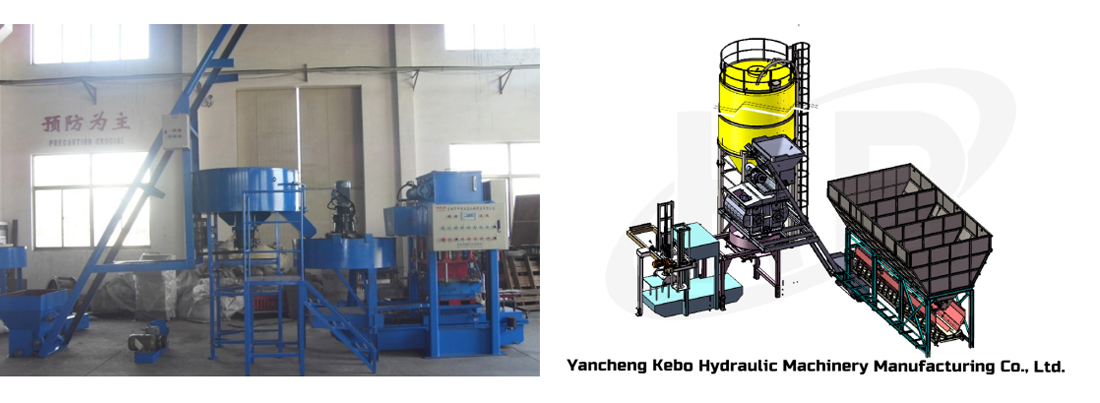

The production line is composed of an Elevator, Mixer, Doser, Palletizer, Host, etc. Use PLC programming, to control each attached machine and host. No need to manually operate a single part. Is a set of mechanical, hydraulic, pneumatic, and automatic control as one. With the advantages of high automation, high productivity, and low labor intensity, it is the preferred product in the building materials industry.

REQUEST A QUOTE

REQUEST A QUOTE

English

English