What is a

Concrete Cement Roof Tile Machine and what are its advantages?

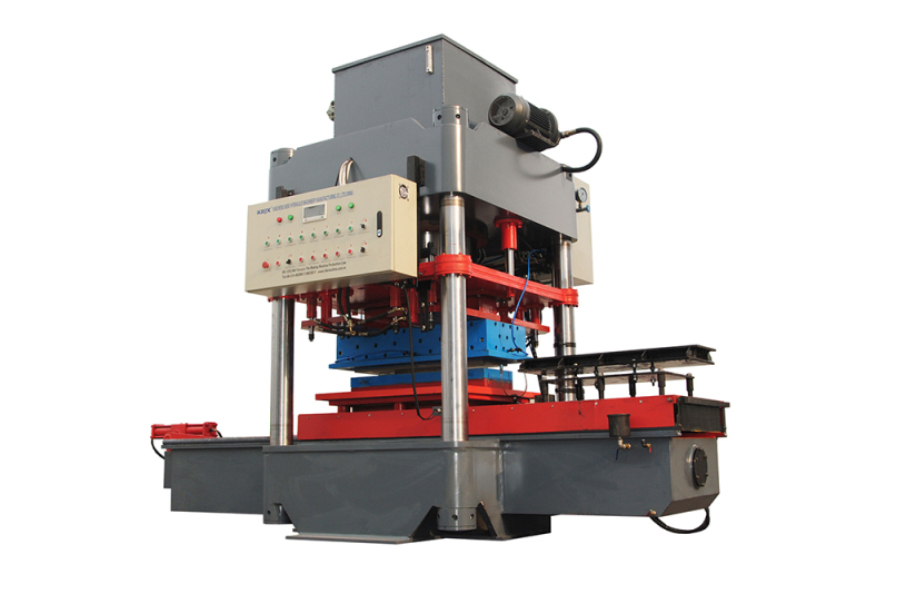

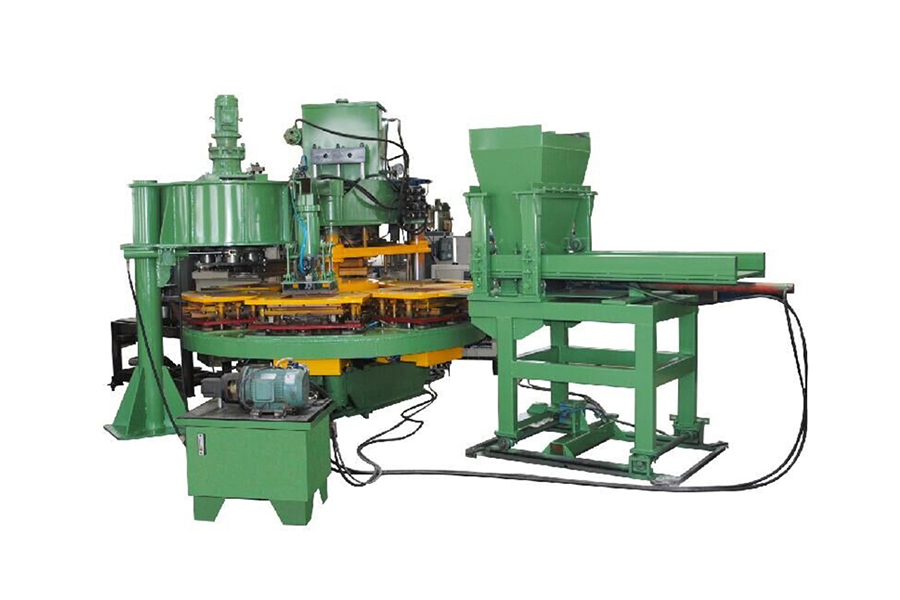

Concrete Cement Roof Tile Machine is a mechanical equipment specially used to produce concrete cement roof tiles. This equipment is widely used in the construction and roof covering material manufacturing industries.

Here are some of the features and functions of the Concrete Cement Roof Tile Machine:

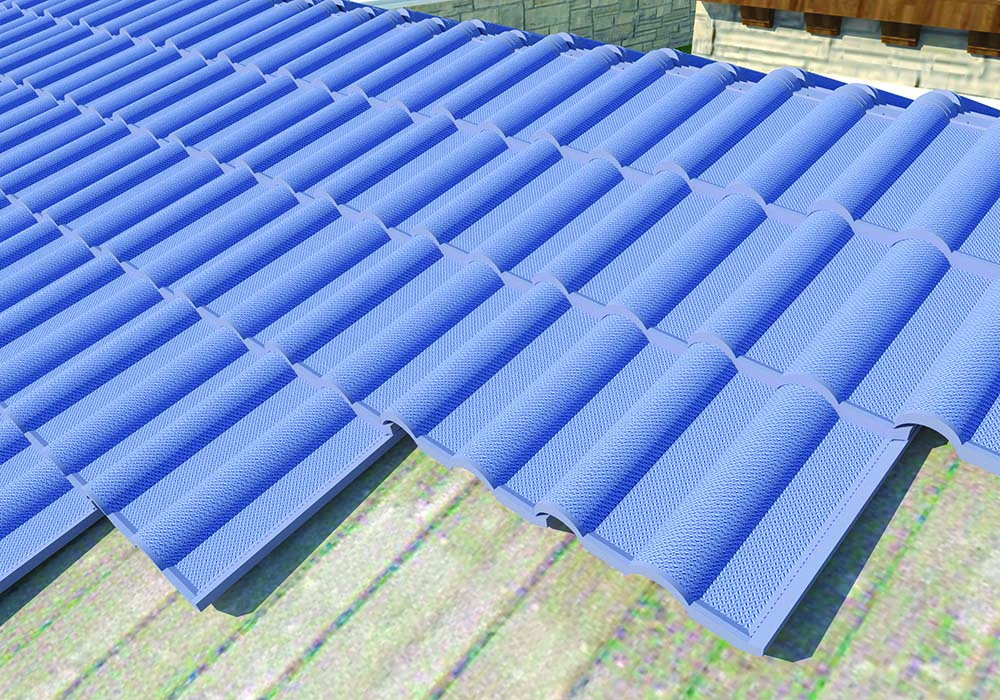

1. Concrete tile production: The main function of this machine is to convert concrete cement mixture into roof tiles with specific shapes and sizes.

2. Mold forming: The Concrete Cement Roof Tile Machine is equipped with molds of different shapes and sizes. Through the mold forming process, the concrete tiles are shaped into the desired roof tile shape.

3. Automated production: Some modern equipment is equipped with automated control systems, making the production process more efficient and precise, and reducing dependence on human operations.

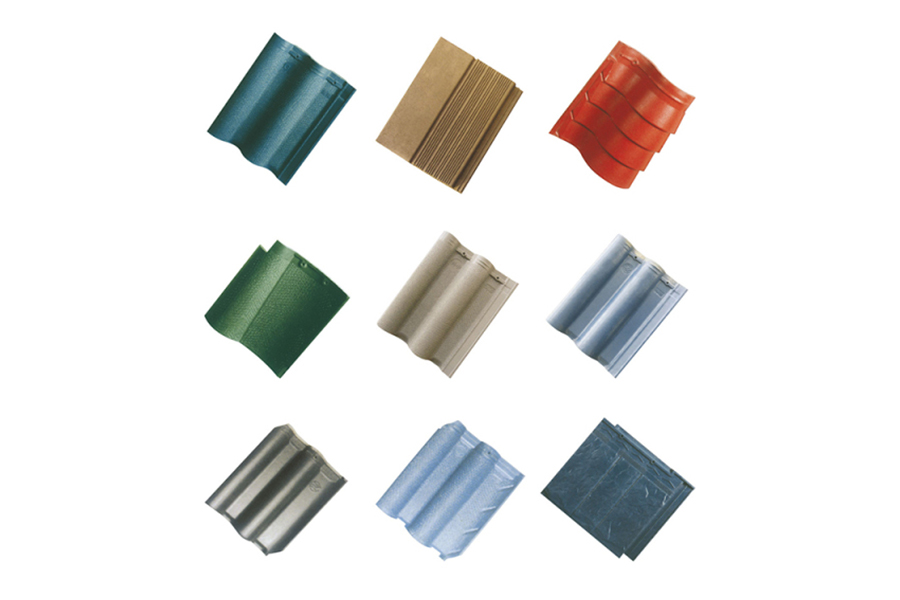

4. Diversified design: The equipment can support the production of cement roof tiles of different designs, colors and textures to meet the diverse needs of the market and customers.

5. High production capacity: Concrete Cement Roof Tile Machine is usually designed with relatively high production capacity to meet large-scale roof tile demand.

6. Durability and stability: Equipment may have a solid mechanical structure to ensure stable operation over a long period of time and to resist wear and tear due to high pressure and vibration during the manufacturing process.

7. Quality Control: Some equipment may include quality control systems to monitor and ensure that each tile produced meets predetermined quality standards.

8. Save labor costs: Automation features may reduce manual operations on the production line, reduce labor costs, and improve production efficiency.

REQUEST A QUOTE

REQUEST A QUOTE

English

English