In the production process of Terrazzo Tile Machine, it is crucial to ensure that the density and strength of the tiles reach their optimal state. This not only affects the final quality of the product, but also directly impacts customer satisfaction and market competitiveness.

The selection and ratio of raw materials are crucial. We strictly screen high-quality raw materials such as cement, stone powder, crushed stones, and various natural stone particles to ensure that they have stable physical and chemical properties. At the same time, through scientific proportioning design and precise control of the proportions of various raw materials, the internal structure of the floor tiles can be optimized to improve their density and strength.

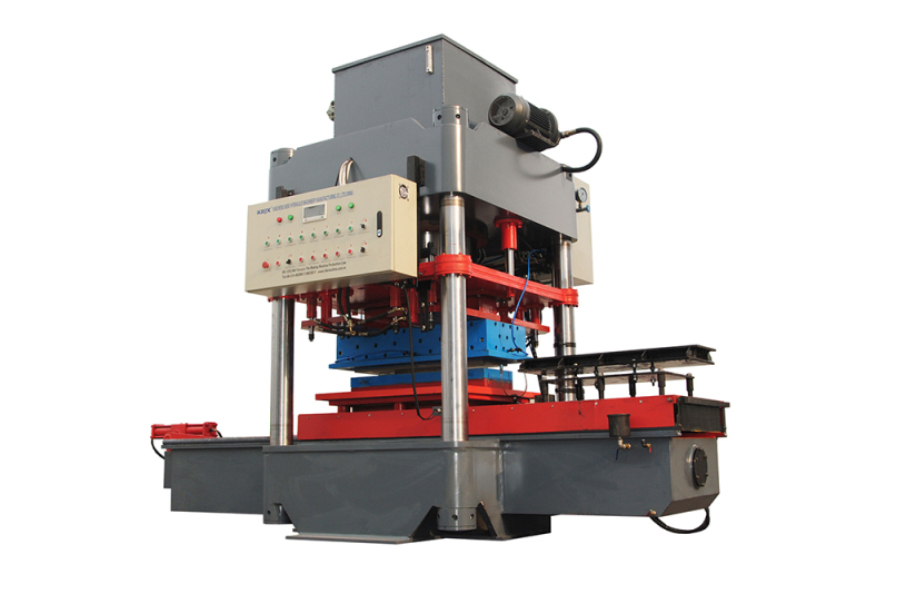

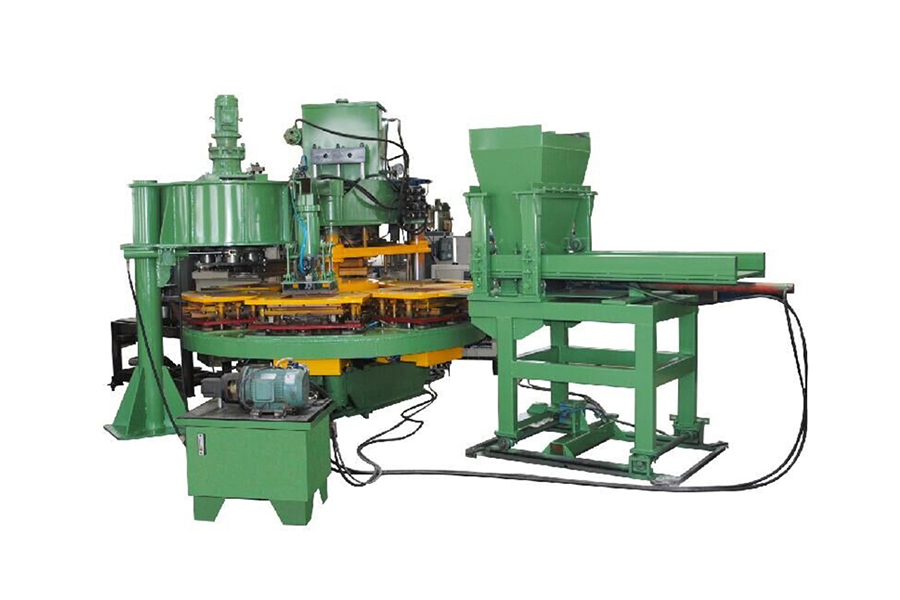

The Terrazzo Tile Machine adopts an advanced high-pressure forming system, which applies tremendous pressure to the mixed raw materials in the mold to tightly bond them and form a dense structure. This process not only increases the density of the floor tiles, but also significantly enhances their mechanical properties such as compressive strength and flexural strength.

In addition, we also pay attention to the fine control of the production process. Through advanced automation control systems, precise monitoring and adjustment of various processes such as mixing, molding, and maintenance are carried out to ensure that each step reaches the optimal state. At the same time, regular maintenance and upkeep of equipment to ensure optimal performance is also an important means of ensuring stable quality of floor tiles.

Tel:+86-15105109068

E-mail:[email protected]

REQUEST A QUOTE

REQUEST A QUOTE

English

English