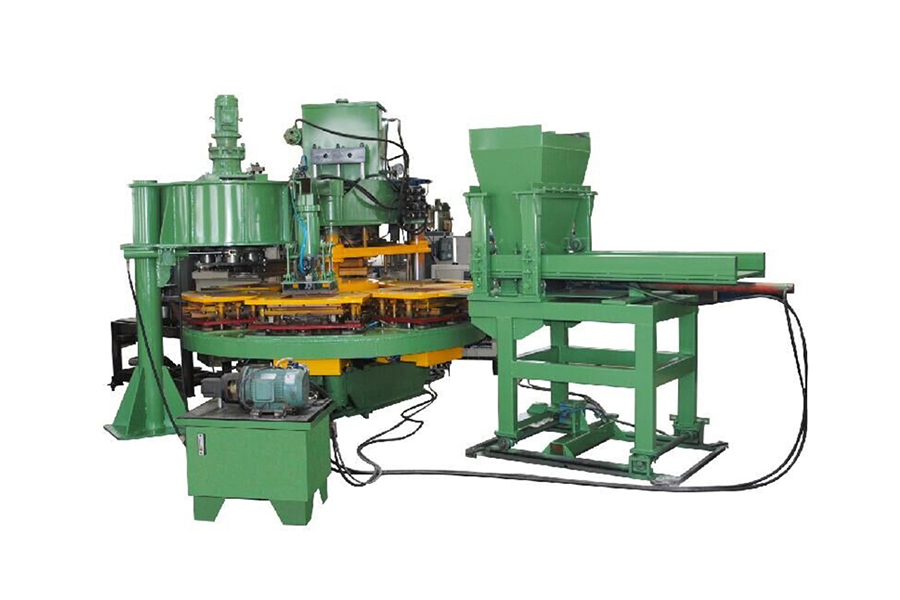

The stripe stone forming machine is an efficient and precise equipment that realizes the stripe and texture processing of the stone surface through mechanical processing and automated control. Its working principle includes several key steps, from the fixing of the stone to the final shaping and quality inspection, each step is carefully designed and strictly controlled to ensure the accuracy and consistency of the processing effect.

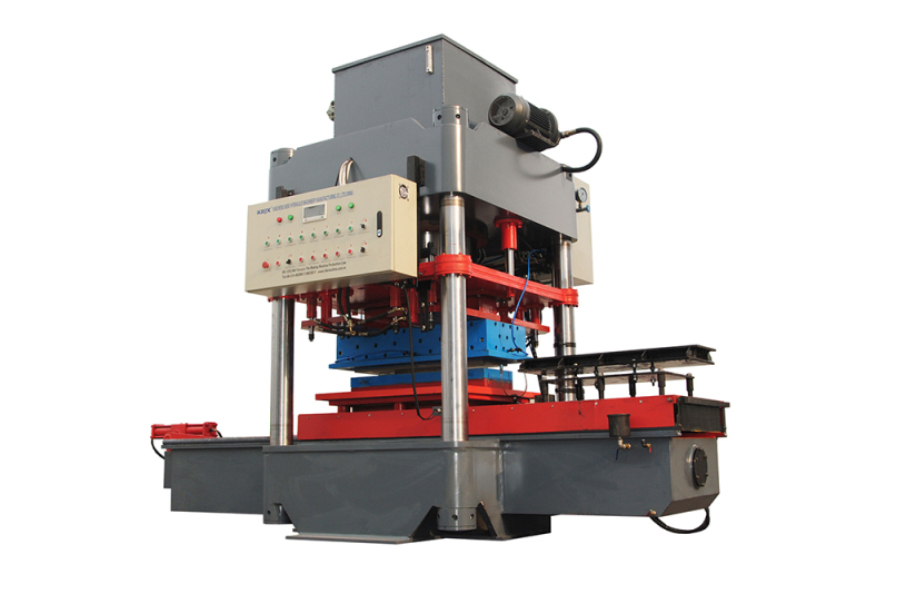

At the beginning of the work, the operator fixes the stone to be processed on the workbench of the machine. This step is crucial because a stable workpiece can ensure accuracy and consistency during the processing. The operator sets the required processing parameters through the control panel or computer programming. These parameters include stripe pattern, depth, spacing, processing speed, etc., which are adjusted according to the design requirements. This step requires precise technology and a deep understanding of the characteristics of the stone to ensure that the final processing effect meets the expectations.

Then, the tool starts working. The tool is driven by a motor and moves on the stone surface according to the set path and speed to cut and form the desired stripes or textures. These tools are usually made of high-hardness alloy materials, have good wear resistance and cutting performance, and can maintain a stable working state during the processing.

During the processing, in order to prevent the tool and stone from overheating, coolant is usually used for cooling and lubrication. Coolant can effectively reduce processing temperature, reduce tool wear, and improve processing quality and efficiency. At the same time, the built-in dust removal system collects the generated stone powder and debris, keeps the working environment clean, and prevents dust from causing harm to the machine and operator.

Throughout the processing, the machine automatically controls the processing process through the CNC system and monitors in real time to ensure high precision and consistency. These advanced control technologies can accurately control the tool's movement path, processing speed and cutting depth to achieve precise processing results.

After processing, the stone is automatically unloaded and quality checked. Quality inspection usually includes an inspection of the stripe effect to ensure that it meets the predetermined standards and design requirements. If necessary, the stone can be further cleaned and polished to enhance the gloss and texture of its surface.

REQUEST A QUOTE

REQUEST A QUOTE

English

English